Overview

A Chinese manufacturer of ready-mixes for the preparation of a national dish set out to automate the final packaging of the bags, thereby increasing productivity and reducing the physical strain on workers. By installing 16 Stäubli SCARAs, the company easily achieved its objectives.

Problem

Automating the packaging process has enabled the food manufacturer to improve productivity and relieve its employees of repetitive work.

Solution

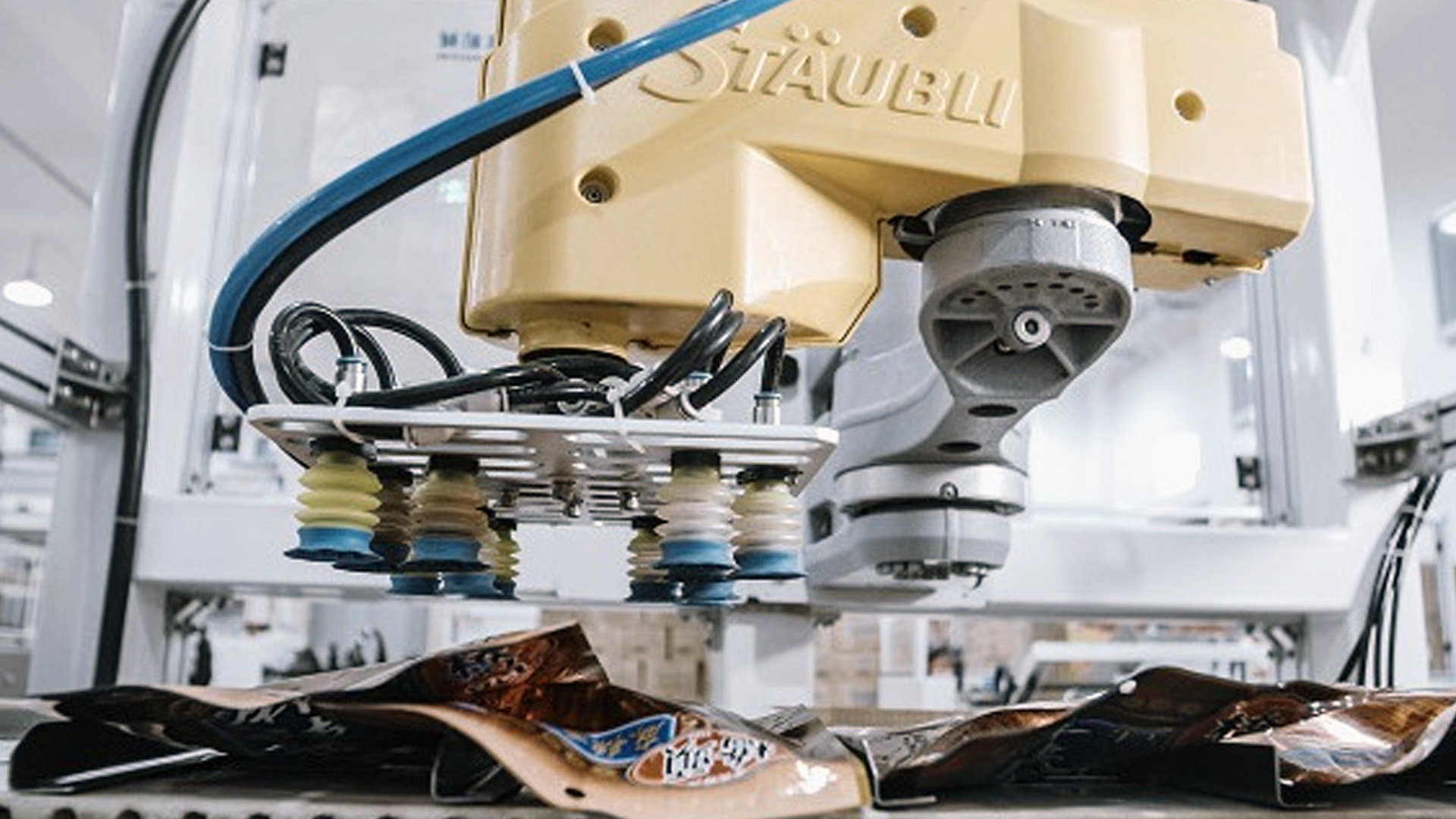

The packaging line for the hot pot bags has no fewer than 16 Stäubli TS60s. The soft bags arrive on a conveyor belt and the four-axis machine picks them up four at a time with vacuum grippers and places them in a box. This is repeated eight times, as each box contains 32 bags. The cycle time of a single robot is approximately 2.7 seconds. Production speed is currently a continuous 90 packs per minute. This means production capacity can be significantly increased in order to easily manage a further increase in demand.

- Reduction of physical strain on employees

- Increased productivity Capacity can be readily increased

- High level of reliability and availability

No comment yet, add your voice below!