Overview

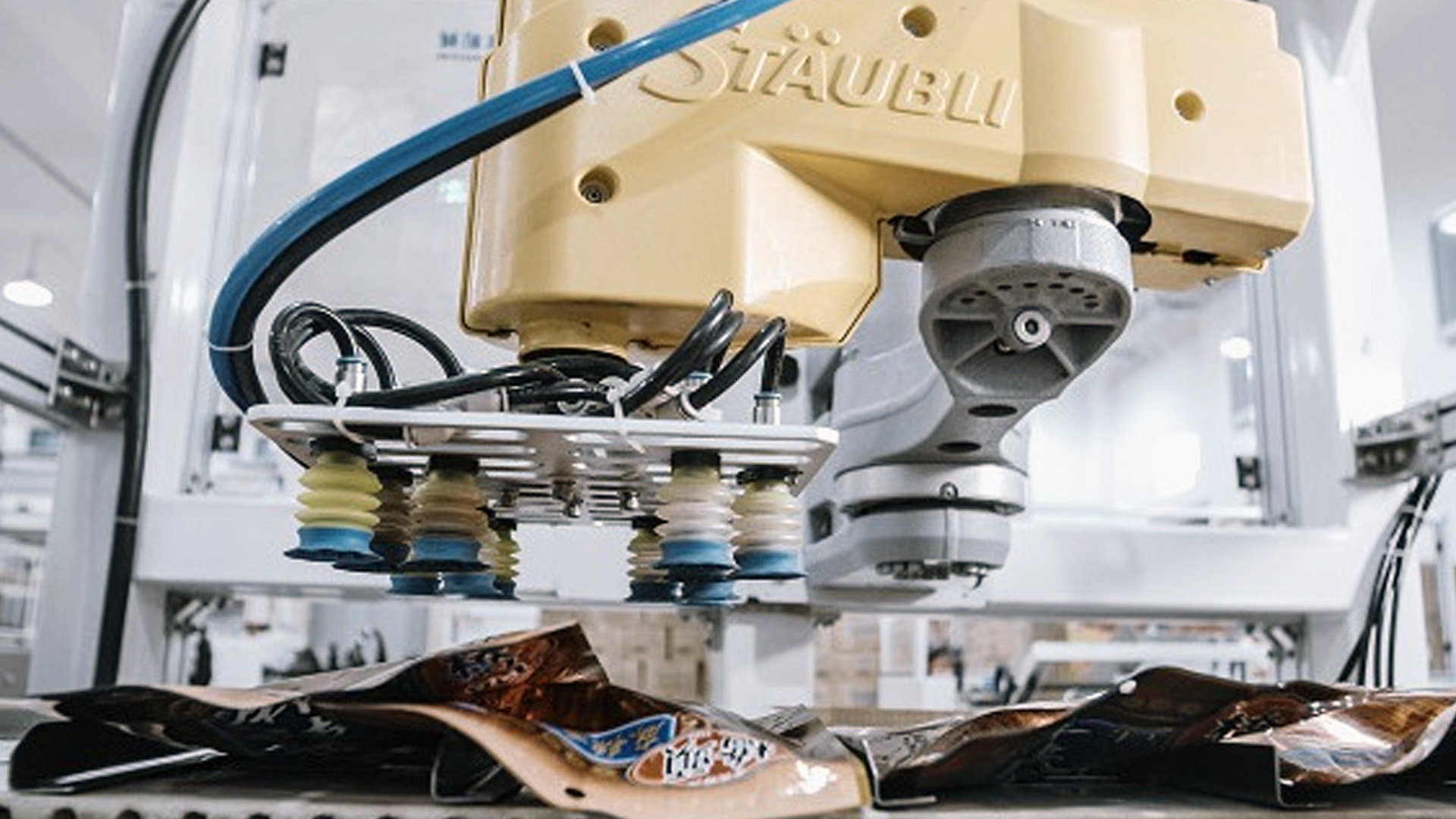

Solutics manufactured a turnkey sachet packing system, capable of handling irregularly delivered product and sorting it into ‘shelf ready’ packaging, ensuring logo placement and sachet positioning was within specific acceptance criteria.

The system is capable of inspecting 1,200 parts per minute (10 per second) and uses a bespoke turning and orientating device to ensure that each sachet is correctly positioned before it is placed into final packaging.

Problems

Sachets arrived with no control over orientation, they could also be top/logo up or down. The customer manufactures over 200 different SKU variants, all with different visual and geometric parameters.

Solution

A modular delta pick & place system was installed along with a Solutics orientator that was specifically tailored to the customer’s sachet system. A Neural AI vision system calculated which robot would be best to pick and orientate each sachet in less than 0.01 seconds after the vision system inspected each newly arriving sachet.